When Peter Horch started his roofing company, he would drive his pickup truck full of roof waste to the Camden dump and turn downhill into the landfill to unload it by hand. As time went by and his business grew, he stopped making those trips himself. One fall, Peter had to fill in for an employee, and he was stunned by what he saw. The same hole at the landfill that he’d driven down into five years earlier had become a huge mountain that he now had to drive up onto to deposit his roofing debris.

“I then realized that I was driving up over my own debris – debris that I’ve pulled from peoples’ roofs,” said Horch. “That mountain is never going to go away. It will be there until my great-grandchildren are living here. And I thought, ‘I just don’t want to do it anymore.'”

While that realization stayed with him, it wasn’t until he attended the Juice Conference in Camden in November 2009 that the idea really began to form. “The conference was about being creative and innovative, so I asked myself what I could do differently. We already offer every type of roofing. We are already different enough in our professionalism, so I thought I could do something else with our debris,” explains Horch.

“Each year Maine produces over 100,000 tons of re-roofing waste that ends up in landfills,” says Horch. “We realized that our company alone was generating about 2 tons (4,000 lbs.) of waste each day accounting for over 1,500 tons (3 million pounds) a year. We wanted to do something about our share.”

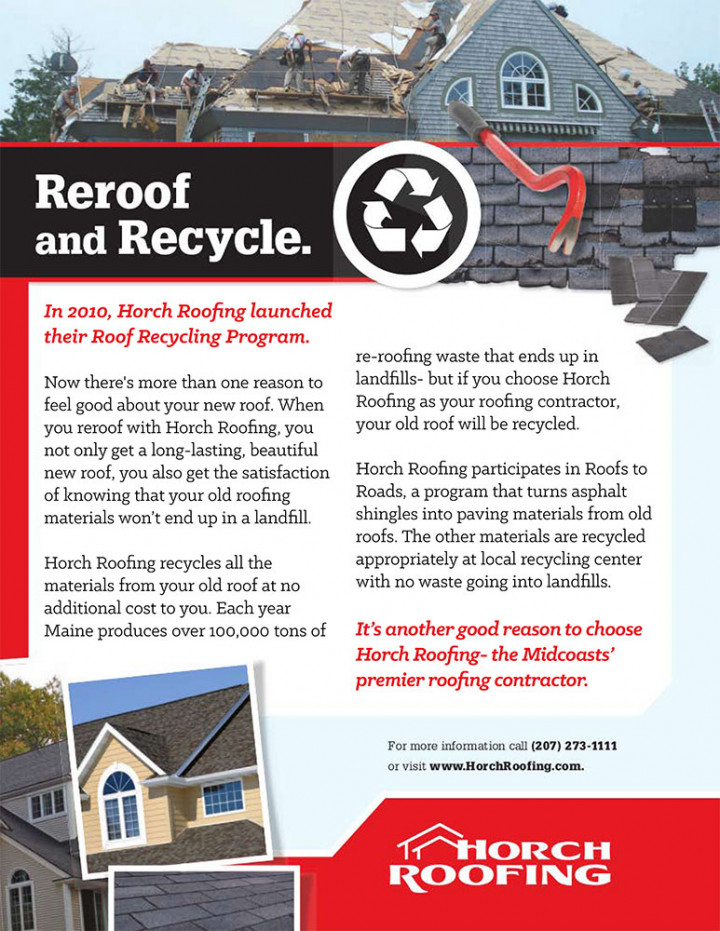

Beginning April 1, 2010, Horch Roofing began their Reroof and Recycle Program, recycling 100% of its roofing waste. The company has discovered that there is both an interest and a need among their clientele, which ranges from small residential projects to large commercial buildings.

Recycling is now part of the culture at Horch Roofing. We partner with Pine State waste to recycle cardboard, paper, glass aluminum and steel. At one of our locations in Warren, a holding pit temporarily houses the re-roofing debris until it can be transported by Doug Fales, another local contractor, to CPRC Group, a company in Scarborough that converts waste into recycled products.

John Adelman, CEO of CPRC Group, explains that the roofing debris is first “source separated.” During this process, a large magnet is used to separate the metal nails from the asphalt shingles. The nails are then cleaned and sent to the metal market. The shingles are ground up and combined with other recycled products to become a recycled aggregate is used on roads, parking lots, and other locations in a way similar to crushed gravel.

Horch Roofing is committed to continuing recycling all re-roofing material as part of its standard operating procedure. “The pure volume and tonnage of material that we now recycle and reuse instead of adding to the local landfill or “landhill” makes this a win-win situation for both my company and community. I sincerely hope that other local construction and roofing contractors are motivated to follow in our footsteps to make every day Earth Day.”

In June 2018, Horch Roofing celebrated 10 million pounds recycled since the start of the program.